Indoor Tight Buffer Distribution

Fiber Optic Indoor Distribution Cable tight buffer with aramid yarn strength member

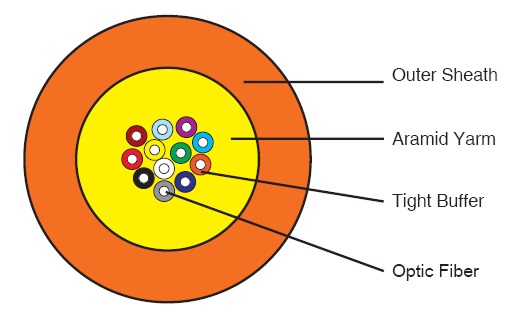

The 900μm tight buffer fibers are distributed in the center of the cable. The aramid yarn as strength member surround the fibers, the cable is completed with a LSOH, PVC or OFNP jacket.

Features:

Features:

- small outer diameter, light weight, easy to strip

- good flexibility performance

- sheath color, SM cable in yellow, MM cable in orange, OM3 cable in aqua, OM4 cable in purple, OM5 in lime green

Compliances:

- ITU-T G651, ITU-T G652D, ITU-T G657A2

- ICEA-596

- ANSI/TIA 568-C.3

- TIA/EIA-492

- IEC-60794,IEC-60793

- IEC-60332-1-2

- RoHS

Applications:

- classical premise backbone cabling fiber optic cable

- 900um tight buffer fiber suits for termination with connectors work as patch cord or pigtails

Drawing:

Ordering information:

| Part No. | 2613xyzzz |

| Description | Premium Line fiber optic indoor distribution cable tight buffer with aramid yarn strength member |

| x, mode | 1: MM 62.5/125 2: SM 9/125 3: MM 50/125 4: MM/OM3 9: MM/0M4 |

| y, outer sheath | 1: PVC 2: LSOH(IEC60332-1-2) 4: OFNP |

| zzz, fiber count | 002 / 004 / 006 / 008 / 012 / 016 / 024 |

Open more information (click on the “+” sign below)

- Structure & Environmental Characteristics

Tight Buffer Material PVC, LSOH or OFNP Peripheral Strength Member Material Aramid Yarn Sheath Material PVC, LSOH or OFNP Color Yellow, Orange, Aqua, Purple, Lime green

Operating Temperature -20oC to +60oC Storage / Transport Temperature -20oC to +60oC Installation Temperature -5oC to +50oC - Mechanical Characteristics

Fiber count Outer diameter (mm)

Nominal cable weight (kg/km) Crush Resistance N/100mm Tensile load Bend radius Short term (N)

Long term (N)

Static (mm)

Dynamic (mm)

2 3.2 10 1000 660 200 10D 20D 4 4.8 18 1000 660 200 10D 20D 6 5.1 22.5 1000 660 200 10D 20D 8 5.6 28 1000 660 200 10D 20D 12 6.2 38 1000 660 200 10D 20D 16 8.0 53 1000 660 200 10D 20D 24 8.2 63 1000 1320 400 10D 20D - Fiber Color Code:

No. of fiber 1 2 3 4 5 6 Color of fiber Blue Orange Green Brown Grey White No. of fiber 7 8 9 10 11 12 Color of fiber Red Black Yellow Violet Pink Aqua No. of fiber 13 14 15 16 17 18 Color of fiber Blue/ Orange/ Green/ Brown/ Grey/ White/ Black Tracer Black Tracer Black Tracer Black Tracer Black Tracer Black Tracer No. of fiber 19 20 21 22 23 24 Color of fiber Red/ Black/ Yellow/ Violet/ Pink/ Aqua/ Black Tracer White Tracer Black Tracer Black Tracer Black Tracer Black Tracer - Indoor Tight Buffer Distribution Fiber Optic Cable, LSOH

Number of Fibers 9/125 50/125 62.5/125 50/125(OM3) 50/125(OM4) 4 261322004 261332004 261312004 261342004 261392004 6 261322006 261332006 261312006 261342006 261392006 8 261322008 261332008 261312008 261342008 261392008 12 261322012 261332012 261312012 261342012 261392012 24 261322024 261332024 261312024 261342024 261392024 - Optical Performance:

Wavelength 9/125 μm 50/125 μm 62.5/125 μm 50/125μm(OM3) 50/125μm (OM4/OM5)

Max. Attenuation dB/km

850 / 1300nm — £ 3.2 / £ 1.2 £ 3.2 / £ 1.2 £ 3.2 / £ 1.2 £ 3.2 / £ 1.2 1310 /1550nm £ 0.36 / £ 0.22 — — — — Minimium Bandwidth MHz· km 850 / 1300nm — 500 / 500 200 / 500 1500 / 500@LED 3500 / 500@LED 2000 / 500@Laser 4700 / 500@Laser wavelength 9/125 μm Max. Attenuation (dB/km) 1310 /1550nm £ 0.36 / £ 0.22 Uncabled fibre macrobending loss ITU-T G.657.A2 fiber Radius (mm) 10 7.5 Number of turns 1 1 Max. at 1550 nm (dB) 0.1 0.5 - Packing Information:

- cable be wound on an iron stand-wooden composite

- standard drum length is 2000m ±1%

- covered by plastic buffer sheet

- sealed by strong wooden battens

- at least 1m of inner end of cable should be reserved for testing

- test protocol at side of the drum

You may also need